YG11C YG15 YG15C Rodas de carburo de tungstênio cimentado para rolos de moagem a alta pressão Rodas HPGR

Detalhes do produto:

| Lugar de origem: | Hunan, China |

| Marca: | Rixin |

| Número do modelo: | 20x45 |

Condições de Pagamento e Envio:

| Quantidade de ordem mínima: | 1 |

|---|---|

| Preço: | $49 |

|

Informação detalhada |

|||

| Material: | Carboneto de tungstênio | Tratamento de superfície: | Concluir aterrado |

|---|---|---|---|

| Nota: | YG11C, YG15, YG15C, YG18, YG20 | TRS: | > 3000 N/mm3 |

| Dureza: | 85-92 HRA | Vida de serviço: | 10.000 - 30.000 horas |

| Fonte de energia: | Elétrico | Tipo de motor: | Elétrico |

| Superfície: | Revestido | Tamanho: | Personalizado |

| Uso: | Rolo de moagem de alta pressão, minério de ferro, britagem de cimento | Desempenho: | Alta dureza, resistência, resistência ao impacto |

| Densidade: | Alto | Resistência ao desgaste: | Alto |

| Resistência ao Impacto: | Alto | ||

| Destacar: | YG11C Pedaços de carburo de tungstênio,YG15 HPGR Studs,Pedaços de carburo YG15C |

||

Descrição de produto

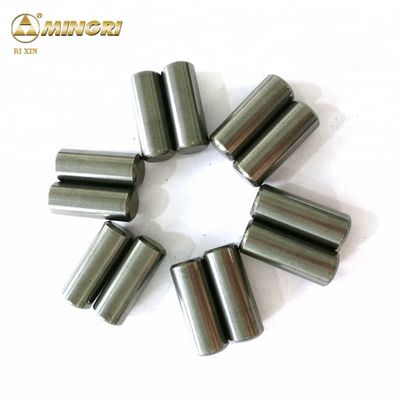

Produto de fabricação original (OEM) Cabeça de bola de ferro personalizável Roller Grinding Press HPGR Studs Pins Cementados Peças de ferramentas de carburo de tungstênio

Visão geral do produto

| Ponto | Outros, de aço |

|---|---|

| Grau | O número de unidades de produção é o seguinte: |

| Tamanhos | Padrão ou personalizado |

| Marca | Rixin |

| País de origem | Zhuzhou, China |

| Utilização | Rolamentos de moagem a alta pressão, minério de ferro, trituração de cimento |

Os pinos de carburo de tungstênio são amplamente utilizados nos rolos de rolamento de moagem a alta pressão.Estes pinos melhoram significativamente a vida útil e a eficiência de trabalho das máquinas HPGREm comparação com os rolamentos tradicionais de cara dura, os pinos de carburo de tungsténio oferecem até 10 vezes mais vida útil.

Especificações técnicas

Tamanhos e tipos disponíveis

Embalagem e entrega

Capacidades de fabrico

Especializamo-nos em todos os tipos de perfis e matrizes de carburo de tungstênio, ferramentas de corte, ferramentas de mineração, peças de desgaste e peças de ferramentas personalizadas não padrão com alto desempenho na indústria.

Garantia da qualidade

Nosso processo de produção inclui mistura de pó, prensagem, sinterização, acabamento e tratamento de superfície..

Todos os produtos são submetidos a uma inspeção ultra-sônica rigorosa antes do envio para garantir que não haja defeitos como poros.

Perfil da empresa

Informações de contacto

Deseja saber mais detalhes sobre este produto